Hannah Desai comes from a family of engineers. Her three older brothers specialize in civil, mechanical and electrical, and aerospace engineering, but after a semester focused on cutting-edge metallurgy research as an FEF intern, Desai knew she wanted to forge her future in metalcasting.

FEF intern Hannah Desai pours molten aluminum for a cast at Virginia Tech’s foundry.

The U.S. casting and forging industry will need 122,000 more skilled professionals by 2028 to meet national production demands. METAL and the Foundry Educational Foundation (FEF) have partnered to accelerate the development of a highly skilled, adaptive manufacturing workforce with hands-on training and internship programs. So far, 16 interns from seven universities have had the opportunity to gain foundry experience before graduating, propelling their careers and strengthening the workforce pipeline.

Desai, a 2025 materials science and engineering graduate from Virginia Tech, was certain she’d go into ceramics before taking her first metalcasting class. She’d never seen molten metal, never experienced the teamwork it takes to melt and shape a material like iron. But after discovering what was possible in Virginia Tech’s foundry, Desai hit the ground running.

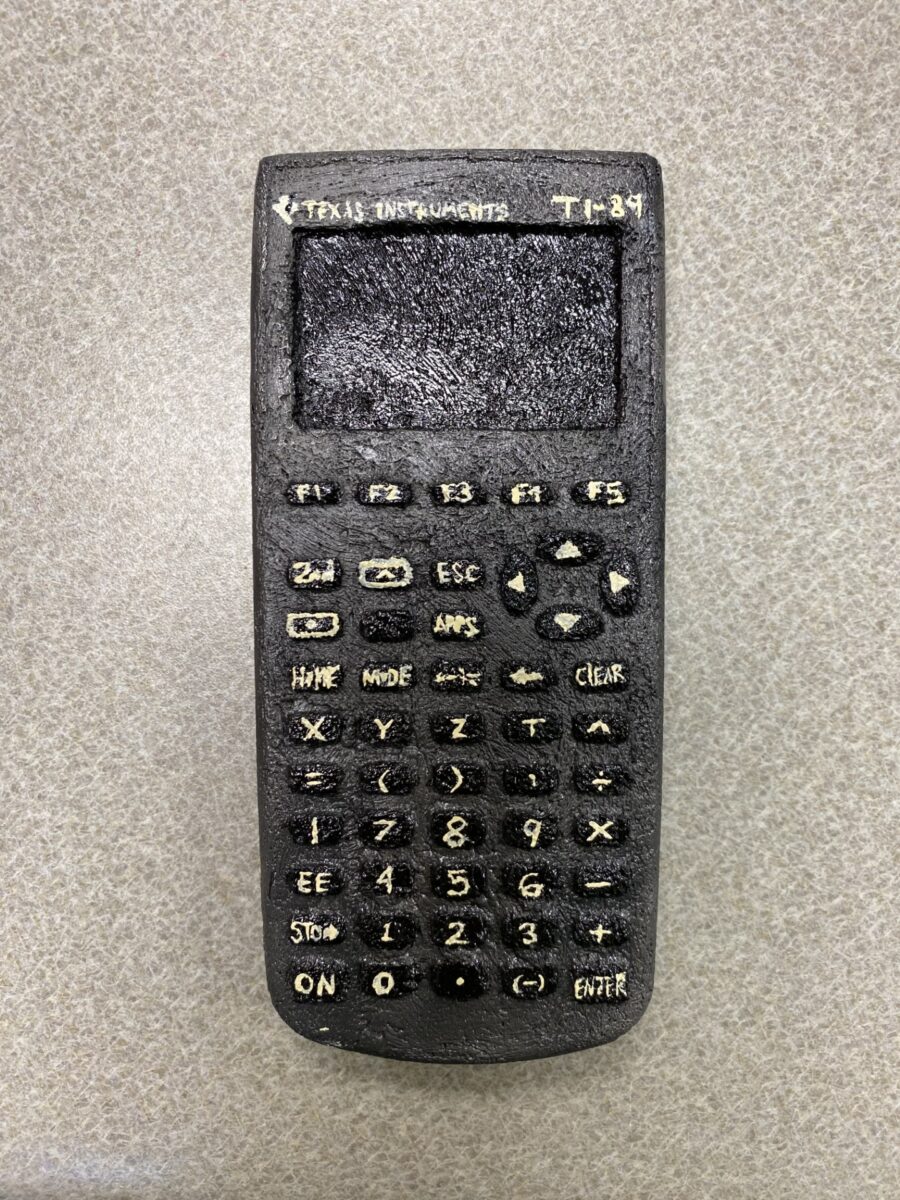

She began to cast everything from HokieBirds and turtles to a detailed TI-89 calculator with inscribed buttons. For her advanced casting lab final project, she took on the challenge of casting small, thumbnail-size steel magnets for the pure joy of trying something new.

“I loved the hands-on learning and seeing the process take place right before my eyes,” Desai said. “It’s different than collecting data. It’s actually seeing the process, being a part of it and then learning something from it.”

Desai carried this enthusiasm and curiosity for metalcasting into her FEF internship experience.

Driving Industry Impact

Hannah Desai, second from left, and FEF Key Professor Alan Druschitz, right, pose with Virginia Tech metallurgy students at the 2024 FEF College Industry Conference.

With guidance from FEF Key Professor Alan Druschitz, Desai applied her chemistry and engineering lessons to real-life foundry projects—from forging new combinations of metals to performing thermal and chemical analyses and even testing the electromagnetics of steel using a forklift battery.

The foundry became Desai’s playground to experiment and learn, and that’s exactly what Druschitz wants for his metalcasting students.

“If a student said, ‘can we come into the foundry and do something on a weekend or an evening?’ the answer’s going to be yes,” he said. “FEF professors are unique because we’re dedicated to the industry and growing the future workforce.”

Druschitz started the metalcasting program at Virginia Tech 15 years ago. Today, the school has an FEF-certified curriculum and operating foundry. Thanks to funding from FEF, Druschitz is able to buy new equipment, award scholarships, and pay student researchers who are eagerly driving the metal industry forward.

Desai joined Druschitz and a team of metallurgy students in researching the impact of adding manganese to ductile iron, a high-strength metal used across manufacturing industries, instead of nickel. Nickel is mixed with ductile iron to make products such as pipes, automotive parts and agricultural equipment more durable in fluctuating temperatures, but it’s more expensive than manganese.

His team’s research could help manufacturers make critical parts stronger and tougher at a lower cost, Druschitz said. “We’ve got the potential for some real industrial significance, and students love that.”

During her internship, Desai learned how to perform heat treatment, modeling, and charge calculations to determine the exact mix of raw materials and ideal melting temperatures for a pour. Then her team turned calculation into action. Together, Desai and three other researchers cast the ductile iron with manganese: two holding the ladle and pouring the molten metal, one running the overhead crane, and another student taking samples.

Desai’s favorite part was seeing the sparks fly—and advancing the future of metal production.

“Research in university foundries is so important because they can do smaller projects that large companies can’t take the time for. That’s why this FEF internship is so special,” she said. “I’m grateful I got the opportunity to help the industry in a small way, but it also made a big impact on my career.”

Forging a Career in Steel

Today Desai works at Gerdau, a leading global steel producer, in the Petersburg, VA steel mill. As a trainee in the G.Future Leadership Development Program, she supports Gerdau’s production of steel products for the agricultural, automotive, construction, distribution, energy, industrial and mining industries—and now she enjoys watching the melt shop’s arc furnace spark as it melts 150 tons of steel.

“It’s really cool to see what I did at the foundry, but on a much larger scale,” she said.

In the future, Desai hopes to continue advancing her education and career in the metalcasting industry. She’s not sure she would have ever explored this passion without her FEF internship and scholarships.

“Without the foundry, I definitely would not be where I am today,” she said. “This experience has been pivotal in my career.”

To learn more about METAL’s FEF internship opportunities, email lcurry@iacmi.org.

Hannah Desai, right, trains with fellow G.Future Leadership Development Program participants in Gerdau’s melt shop in the Petersburg, VA steel mill.

Life-size replica of TI-89 calculator cast by Desai at Virginia Tech’s foundry

Hannah Desai, left, received FEF’s Chester V. Nass Memorial Scholarship in 2024.