Students at Seymour Primary School recently experienced metallurgy first-hand during a live sand casting demonstration at the school’s annual Book Bash celebration. METAL (Metallurgical Engineering Trades Apprenticeships & Learning) and IACMI – The Composites Institute® supported the event by showing students how metal is shaped through a process called sand casting.

Students at Seymour Primary School recently experienced metallurgy first-hand during a live sand casting demonstration at the school’s annual Book Bash celebration. METAL (Metallurgical Engineering Trades Apprenticeships & Learning) and IACMI – The Composites Institute® supported the event by showing students how metal is shaped through a process called sand casting.

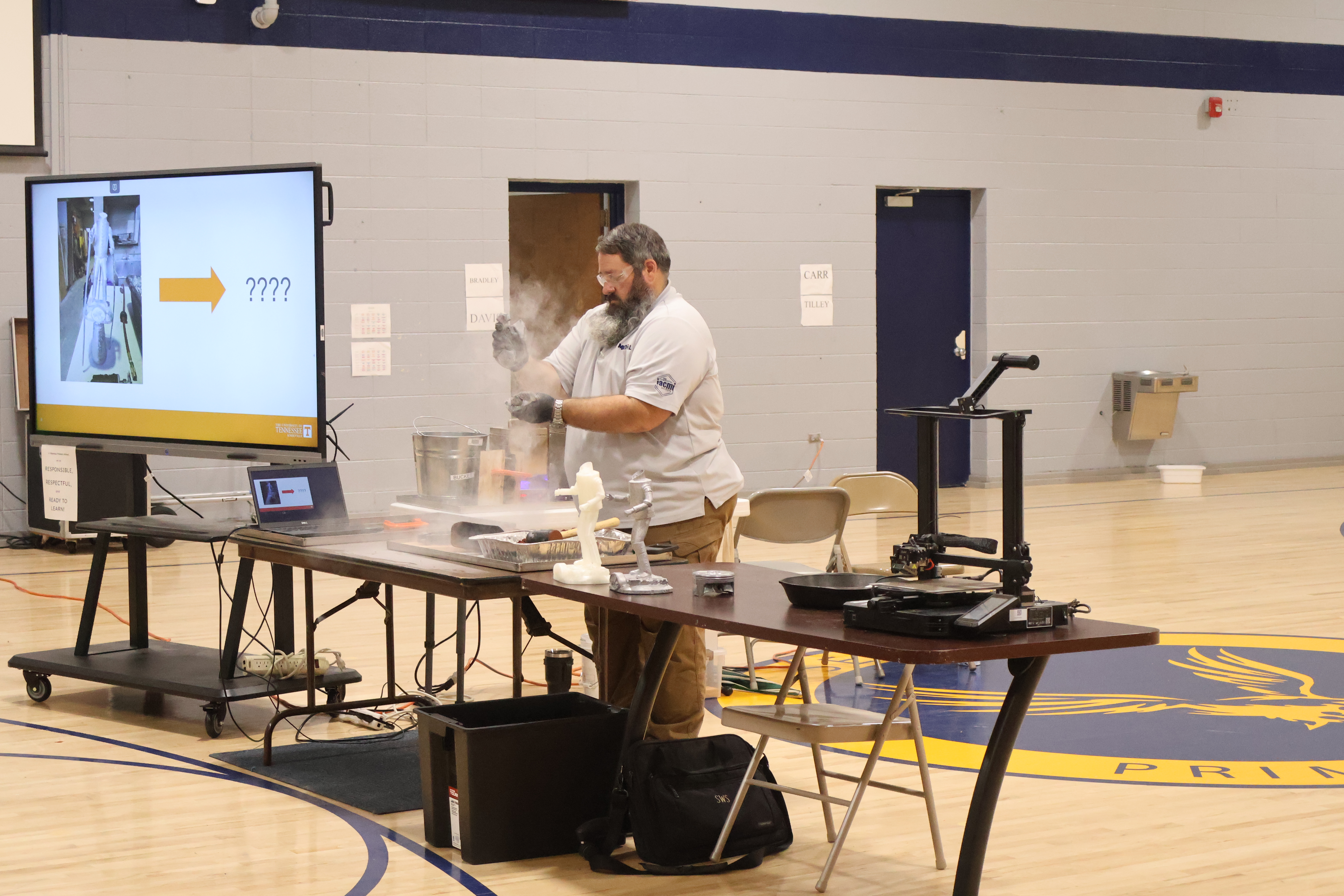

This year’s Book Bash book selection was The Wizard of Oz. Seymour Primary’s Book Bash is an annual celebration of reading that brings the entire school community together. For one month each year, students, staff, families and friends all share the experience of reading the same book. The story inspired school-wide participation in a STEM-focused sand casting presentation, where METAL facilitators used a mold of a Tin Man figurine to pour metal into, bringing the iconic character to life.

The Tin Man casting project served as both a technical demonstration and a creative introduction to the magic of metallurgy, perfectly paired with the school’s elaborately decorated halls, featuring a yellow brick road and an Emerald City.

The Process of Casting the Tin Man

Sand casting is one of the oldest metal fabrication techniques; The process uses compacted sand to form a mold around a solid pattern of the desired object.

Prior to the event at Seymour Primary, team members at the University of Tennessee School of Art and the Tickle College of Engineering collaborated to investment cast a headless Tin Man’s body and base. During the demo, instructors created the Tin Man’s head mold by tightly packing specialized sand around a 3D-printed pattern. Once the mold was removed and the cavity formed, instructors melted tin to over 600°F and poured it into the mold.

The room erupted into ‘oohs’ and ahhs’ when students learned the metal had to be heated to 600 degrees. After cooling, instructors broke the sand mold away, revealing a solid metal replica of the Tin Man’s head.

Igniting Curiosity Through Creativity

“We’re taking a character from the book, the Tin Man, and we’re talking about engineering principles, like 3D modeling, 3D printing and metal casting,” said Stephen Sheriff, Process Engineer and Research Associate II at the University of Tennessee’s Fibers and Composites Manufacturing Facility in Knoxville. “But beyond the science, it’s about sparking creativity, whether it leads to a career or just a new curiosity.”

Following the demonstration, students were curious and eager to ask questions. They wanted to know where the metals came from, what materials can be melted and how various metals are molded.

Building the Workforce of Tomorrow

Sand casting demonstrations aren’t just about science; they help students explore future opportunities in critical career fields.

“We’re hoping to spark students’ interest in trades like metallurgy and help fill critical workforce gaps in areas like ship and submarine building for the Department of Defense,” said Greg Harrell, Workforce Coordinator at IACMI.

METAL is part of a larger effort, supported by the Department of Defense, to build a robust pipeline of skilled tradespeople. By introducingthese concepts early, the METAL program aims to inspire the next generation of metallurgical engineers, technicians and craftsmen.

“The key takeaway is that this kind of creativity and problem-solving isn’t out of reach,” said Sheriff. “With some imagination and the right tools, an idea can become a finished project.”

Interested in Hosting a Workshop or Live Demonstration?

Sand casting is just one of the many techniques METAL uses to introduce students to the world of casting, forging, manufacturing and design.

Demonstrations like these offer students a firsthand look at traditional metalworking processes, helping them understand how raw materials are transformed through engineering and craftsmanship. Watching an idea come to life shows students the diverse applications of metallurgy – both creative and functional – and offers an introduction to the industry.

To learn more, visit: metalforamerica.org